Most of the work has moved inside now, with many of the trades in every day finishing trim, tile, painting, doors, and mechanical and electrical systems.

Our custom-made kitchen range hood arrived last week from the metal fabricator, All Metal Fabricators, Inc. in Acton, MA, and was installed and hooked up to the ductwork. It’s an unusual hood in that it’s significantly wider than the range it sits above. We designed it this way to ensure the best coverage of the cooking surfaces and to maximize ventilation from the gas range and adjacent electric induction cooktop. The hood conceals a Best IQ Blower System designed to remove smoke and cooking byproducts faster and more quietly than similarly-sized fans. Over the next few weeks our HVAC contractor will get the system running, calibrated, and interlocked with the makeup air fan.

Speaking of which, the makeup air system was also installed last week. Because we’ve built such an airtight home, a source of outside air is necessary to maintain equilibrium pressure in the home when the kitchen range fan is running. The makeup air fan in the basement draws fresh air in from outside, preheats it if necessary, and then exhausts it into a basement common space where it can flow into the kitchen to maintain pressure.

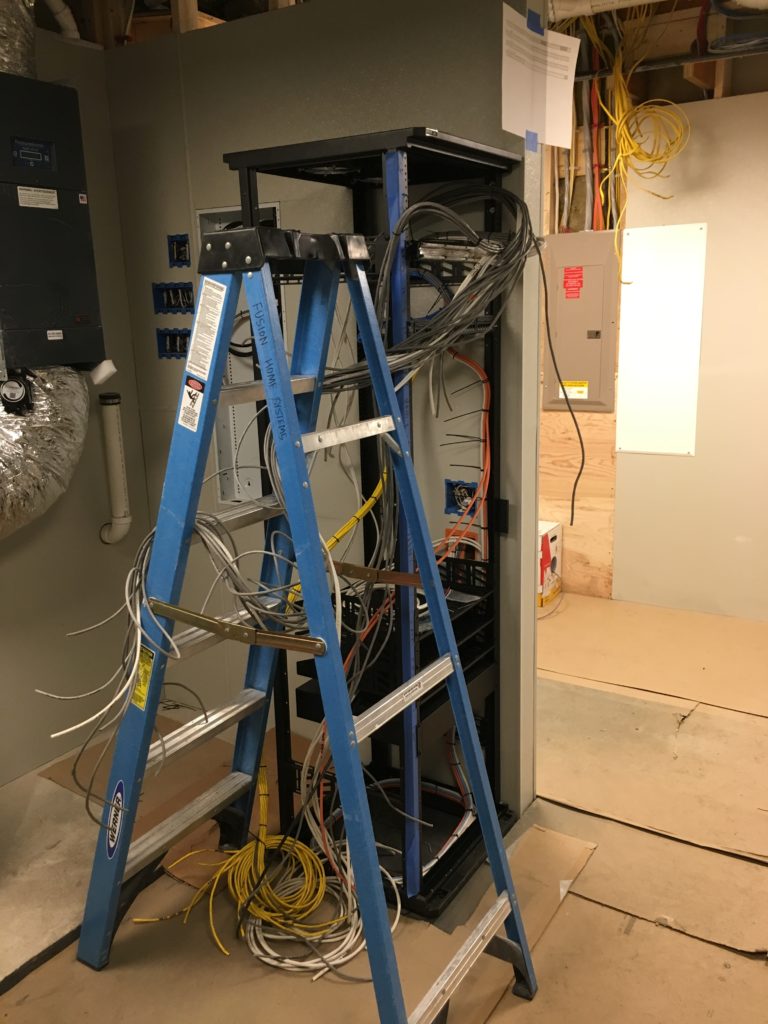

The makeup air system has been placed in the basement mechanical room, where there’s lots of other activity going on as well. First, our tile mason put down an attractive and durable tile floor to provide a smooth and finished work surface. Then the electricians from our smart house & technology contractor, Fusion Home Systems in Cambridge, MA, brought in the equipment rack and have been busy wiring all the sound, lighting, audio/video, internet and wi-fi, and other services into the structure.

Upstairs the masons and carpenters are working on wall and bathroom finishes. Most of the bathrooms are tiled now and our shower door contractor was out to measure for the glass. Our carpenters are doing the detail work on the stairs and installing our shiplap wall siding in the front foyer – where it will run from the basement to the third floor – and in the yoga room over the garage. The painter contractor is finishing up rooms as they become available, and we expect our flooring to arrive very soon.