Earlier this year we designed and built a couple of small wall mockups to demonstrate the differences between the highly-insulated wall assembly we’re using on this project and the typical, code-built wall. Each mockup is a cross-section so you can see the different materials that constitute each wall. Our team member Craig used these in a presentation at NESEA in March to great effect, as props to show how builders can explain building elements that are usually not visible to the consumer or appraisers. In this photo, the code-built wall is on the left, our high-performance wall is on the right.

Follow the show we decided to carry our mockup demonstration one step further, and so Walter’s carpenters at Essex built a “hotbox” that we could use to measure the thermal performance of each wall section. They built an insulated box with a heater in it, large enough to hold the two sections side-by-side, and then on a cool morning in the spring we heated the interior of the box to about 120F and used an IR camera to photograph the exterior surfaces of each wall.

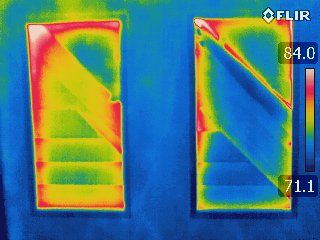

In these images the blue colors are cooler and the red colors are warmer. The wall on the left is built to the current building code, while the wall on the right is the one we’re using on this project. The major takeaway is that the left wall is warmer (more red and yellow) and the right wall is cooler (more blue), which shows the improved thermal performance of our design. The IR images can’t capture one of the big advantages of our wall design: by using exterior insulation, we can significantly reduce “thermal bridging” through the wall studs. In the IR image of the Shornecliffe project, the outlines of the wall studs and braces are clearly visible because they are conducting heat around the insulation in the wall cavities (we did not use exterior insulation in this project).