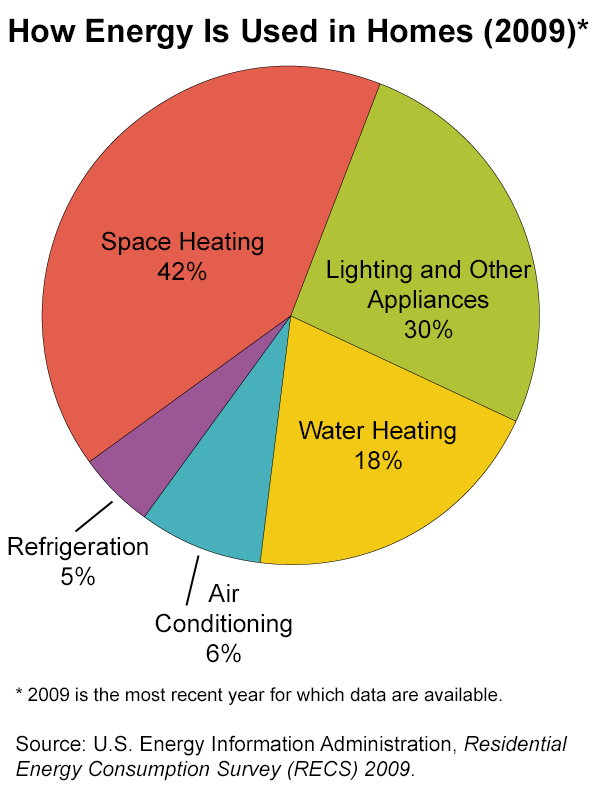

We’ve put a lot of effort into the design of the hot water system. In the average home, hot water is the third largest energy use (18%), behind heating and cooling (48%) and lighting, appliances, and electronics (30%). In the Highland project, due to the super insulation and efficient systems, heating and cooling will be a smaller percentage of total energy use and water heating will be more important. This post will highlight a few of the strategies we’re using to minimize energy use. In a future post I’ll discuss our low-flow water fixtures and our other strategies to conserve water.

Our major plumbing features are: a heat-pump water heater that is many times more efficient than a typical electric water heater (but we have an electric tank too for extra capacity); a Structured Plumbing© system consisting of three recirculation loops that run through the entire house, to ensure that hot water is always just a few feet from any fixture; a set of adaptive recirculation pumps, which keep hot water in the main lines but “learn” water use patterns so they don’t run unnecessarily; and finally a set of well-insulated hot water lines to minimize heat loss throughout the home.

We’re using the Rheem Prestige hybrid heat pump water heater. Unlike an electric resistance water heater, which uses a heating element to heat water, the HPWH uses the heat that’s in the air itself as the source of heat for the water. This allows heat pump water heaters to be 3-4 times more efficient than regular water heaters. This Rheem unit will do the majority of the water heating in our system. Next to it is a Rheem Marathon electric water heater. Most of the time this unit will just act as a large storage tank, so there’s always plenty of hot water available. During high demand periods it will also heat water, albeit less efficiently. Overall, it’ll be a system that is very efficient and that can handle a large hot water load in a short period of time.

Our “Structured Plumbing ©” system is a carefully-designed set of loops throughout the house that carry hot water past every “wet room” (rooms that use water). The system is optimized to minimize length from the loop to each fixture, so there’s no long wait for hot water when you turn on the tap.

Recirculation pumps force the hot water through the main loops and around the house. Recirculation pumps represent a trade-off between efficiency and convenience. At one extreme, we could set the pumps to run 24/7 and there would always be hot water in the loop near each fixture; the disadvantage is that this would use a lot of energy to keep the pumps running continuously. At the other extreme are “demand” loops, in which the pump comes on when the user activates a switch to tell the system to send hot water. These are most efficient (the pump only runs when needed), but the flip side is a delay while the hot water loop heats up. We’re taking a middle road: using the new Grundfos Comfort PM AutoAdapt pumps, which will “learn” water usage patterns and recirculate water at appropriate times. They have other settings which can allow them to operate more like regular recirc pumps depending on the user’s needs.

Finally is pipe insulation. A sheath of pipe insulation over the hot water pipes helps reduce heat loss, keeping the water warm longer and so requiring the recirculation pumps to run less frequently.

Put together, we expect to get a hot water system that uses less energy but that provides more hot water, faster, than a regular system.